Threadlockers are essential in mechanical assembly, keeping fasteners secure in everything from industrial machinery to household appliances. Loctite, a well-known brand in the adhesive industry, offers several products tailored for different threadlocking needs. Among these, Loctite 243 and Loctite 222 are two popular choices that cater to specific applications and use cases.

This article explores the differences, benefits, and best use cases for Loctite 243 and Loctite 222 to help you make an informed decision.

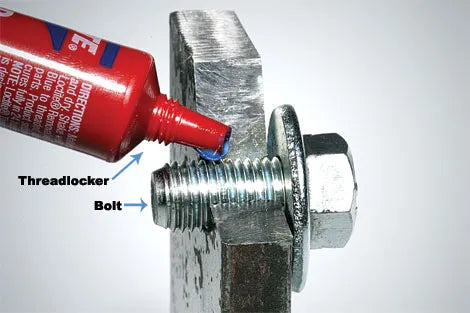

What Are Threadlockers?

Threadlockers are adhesives designed to secure and seal threaded fasteners, preventing loosening due to vibration, shock, and thermal expansion. They are particularly useful in industrial applications where safety and reliability are critical.

Threadlockers are classified by their strength: low, medium, and high. This classification influences how easy it is to remove the fastener after the adhesive has cured. Loctite 243 and Loctite 222 fall into the medium and low-strength categories, respectively, making them suitable for specific applications where different degrees of fastening and removability are needed.

Overview of Loctite 243 and Loctite 222

Loctite 243

Loctite 243 is a medium-strength threadlocker that works well on a variety of materials, including both oiled and non-oiled surfaces. It’s designed to secure fasteners in place, preventing loosening due to vibration and shock, and is widely used in automotive, industrial, and construction applications.

Key Features of Loctite 243:

- Medium Strength: Holds fasteners firmly in place, suitable for applications where dismantling is possible but may require tools.

- Oil Tolerance: Bonds well on surfaces with slight contamination, such as residual machine oil, making it ideal for industrial environments.

- Temperature Resistance: Effective in a temperature range of -65°F to 360°F (-54°C to 182°C), suitable for high-temperature applications.

- Vibration Resistance: Excellent for applications subject to continuous vibration, such as engines and gearboxes.

Best Uses:

- Automotive assemblies

- Heavy machinery

- Power tools

- General-purpose industrial equipment

Loctite 222

Loctite 222 is a low-strength threadlocker known for its suitability on small, delicate fasteners. Its low-strength formulation makes it ideal for applications requiring adjustments, frequent disassembly, or on components sensitive to excessive force.

Key Features of Loctite 222:

- Low Strength: Provides a light bond, making it easier to remove and adjust parts with standard hand tools.

- Controlled Torque: Ensures small screws and fasteners are not overtightened, reducing the risk of damaging threads or delicate components.

- Temperature Resistance: Effective in temperatures ranging from -65°F to 300°F (-54°C to 150°C), making it suitable for less extreme environments compared to Loctite 243.

- Vibration Resistance: While not as robust as Loctite 243, it offers adequate resistance to mild vibrations.

Best Uses:

- Electronics and electrical applications

- Optical devices

- Instrumentation screws

- Low-torque fasteners in appliances

Comparing Loctite 243 and Loctite 222

Strength and Holding Power

- Loctite 243: With medium holding strength, it is suitable for most applications where the fasteners are intended to stay in place during operational use. Loctite 243 offers reliable holding power and requires tools for disassembly, making it ideal for heavier-duty applications.

- Loctite 222: Designed for applications requiring low holding strength, Loctite 222 allows for adjustments and removal with minimal force. This is advantageous for assemblies with delicate fasteners or screws where high torque might cause damage.

Temperature Resistance

- Loctite 243: Performs reliably under a broader temperature range (-65°F to 360°F), making it suitable for use in high-temperature industrial applications.

- Loctite 222: With a slightly lower temperature tolerance (-65°F to 300°F), Loctite 222 is better suited for indoor applications or devices that operate within moderate temperature limits.

Oil Tolerance

- Loctite 243: One of the standout features of Loctite 243 is its oil tolerance. It can be used on fasteners with light surface contamination, like machine oils, which is valuable in industrial or mechanical settings.

- Loctite 222: Loctite 222 works best on clean, oil-free surfaces, as it lacks the oil tolerance seen in Loctite 243.

Vibration Resistance

- Loctite 243: Offers excellent vibration resistance, making it ideal for machinery and automotive applications subject to heavy and continuous movement.

- Loctite 222: Provides basic vibration resistance, sufficient for light applications like electronic devices, but it may not hold up under intense vibrations or shocks.

Practical Application Considerations

When selecting between Loctite 243 and Loctite 222, consider the following:

- Material Type: Loctite 243 is a better choice for metallic materials, whereas Loctite 222 is often used with smaller, more delicate components, including softer metals like aluminum.

- Disassembly Requirements: If the fastener will need to be removed regularly, Loctite 222's low-strength formulation allows for easier disassembly. For applications where removal is rare or would only occur during major repairs, Loctite 243 is preferable.

- Environmental Exposure: For environments with high temperatures or light oil contamination, Loctite 243 is ideal. Loctite 222, being more sensitive, performs best in controlled environments with minimal exposure to contaminants.

Key Takeaways

|

Feature |

Loctite 243 |

Loctite 222 |

|

Strength |

Medium |

Low |

|

Temperature Range |

-65°F to 360°F (-54°C to 182°C) |

-65°F to 300°F (-54°C to 150°C) |

|

Oil Tolerance |

High |

Low |

|

Vibration Resistance |

High |

Moderate |

|

Best For |

Industrial, automotive |

Small, delicate fasteners |

Conclusion

Both Loctite 243 and Loctite 222 offer unique benefits tailored for different applications. Loctite 243 is the better choice for medium-strength needs where oil tolerance and higher temperatures are factors. It’s ideal for automotive and industrial applications that require secure, vibration-resistant fastening. Loctite 222, on the other hand, provides low-strength adhesion that protects delicate components, making it suitable for small screws, electronics, and instruments that need frequent adjustments.

Choosing between Loctite 243 and 222 depends on the specifics of your application, including strength, temperature range, environmental exposure, and the need for disassembly. By understanding the strengths and limitations of each, you can select the threadlocker that ensures reliable performance, safety, and durability for your project.

发表评论

所有评论在发布前都会经过审核。

此站点受 reCAPTCHA 保护,并且 Google 隐私政策和服务条款适用。